Products

1

Bearings and Hydro-dynamic Bushings support the crank.

Bearings and multiple hydro-dynamic bushings are applied to get smaller overall clearance and precise bottom dead center. Hydro-dynamic bushings can not only withstand large reaction forces, but also help the crankshaft rotate smoothly, saving energy and electricity.

Crank Temperature Monitoring system

Crank bushings are equipped with temperature sensors to ensure the effective lubrication of the crankshaft to reduce the down time caused by insufficient lubrication or machine abnormalities.

2

Load Monitoring System

When the loading exceeds the total tonnage, eccentric load or tonnage is abnormal, the system will stop the machine running to reduce the damage to the press and the die.

3

High Rigid Casting Frame

3 sets of high-rigidity casting frames resist deflection and reduce vibration. The deflection of the bed frame is within 0.050 mm/m, which is beneficial to the bottom dead-center accuracy.

4

Dynamic Balancing

Counter balancer reserves the weight of the upper die to eliminate the slide inertia forces produced by reciprocation and reduces pressure vibration.

5

Separate Flywheel & Brake system

The separation clutch and braking system have a short braking time and a small stopping angle. Load balancing at both ends of the crankshaft reduces bearing wear and maintains flywheel rotation accuracy.

6

Plungers and Slide Gibing System

Plungers absorb the lateral forces of continuous motion. Eight-sided gibing system with linear bearings can withstand greater eccentric loads. Multiple plungers help keep slide deflection within 0.05 mm/m.

Slide Quick Lifting System

The slide moves upward 70mm in 60 seconds, helping to release materials and solve die problems. After troubleshooting, the slide returns to the original shut height, and the bottom dead center remains unchanged.

PERFORMANCE

Overall Clearance

< 0.45 mm

< 0.45 mm

Vertical Accuracy

< 0.005 mm

< 0.005 mm

Parallelism Accuracy

< 0.04 mm/m

< 0.04 mm/m

CONTROL

Main Page

Die Information

Load Monitor

Temperature Monitor (Option)

Service Log

Alarm Records

SPECIFICATION

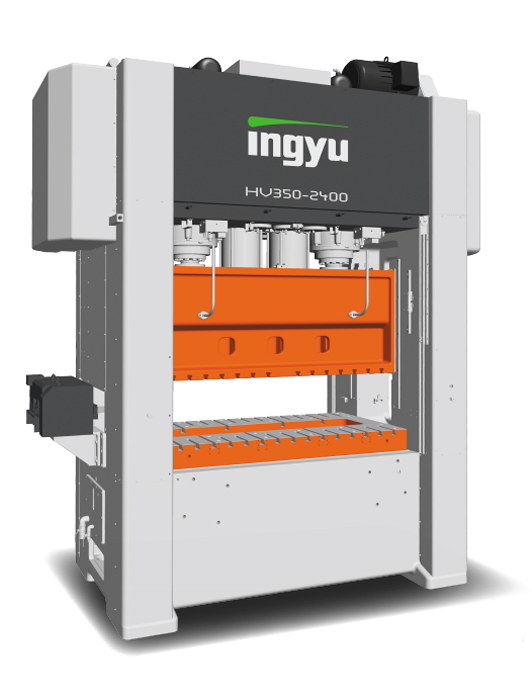

| Model | HV200-1800 | HV350-2400 | |

|---|---|---|---|

| Tonnage Capacity | tons | 200 | 350 |

| No. of Points | points | 2 | 2 |

| Stroke Length | mm | 30 | 30 |

| Stroke Per Minute (No Load) | spm | 200 - 500 | 150 - 400 |

| Die Height | mm | 400 - 450 | 450 - 500 |

| Bolster Area | mm | 1800 x 1050 | 2400 x 1200 |

| Slide Area | mm | 1800 x 700 | 2400 x 800 |

| Slide Quick Lift | mm | 70 | 70 |

| Main Motor | hp | 50 | 75 |

| Max. Upper Die Weight | kg | 800 | 1200 |

| Dimension of Press | |||

| Height of Press | mm | 4450 | 5160 |

| Height for Operation | mm | 1150 | 1400 |

| Width of Bed Opening | mm | 1500 | 2100 |

| Width of Press | mm | 2550 | 3250 |

| Depth of Press | mm | 1700 | 1900 |

| Side Opening | mm | 540 | 620 |

| Weight of Press | tons | 40 | 70 |