Application

Metal products are highly diverse, and different material properties require different metal forming methods. At INGYU, we know that selecting appropriate equipment and methods based on product characteristics and carefully planned production management are crucial. This method not only improves production line utilization and product yield, but is also the key to reducing production costs and gaining competitive advantage through differentiation.

Can Making

Producing easy-open lids requires high-speed and high-precision stamping presses that can operate 24/7. INGYU's advanced solutions include thermal control systems and quick slide lifting device, which can help customers solve die problems efficiently and reduce production line downtime.

EV Motor & Battery

Batteries are essential in numerous applications, powering almost everything around us. INGYU's double action cupping press is designed to enhance battery production efficiency, capable of producing up to 17 cups in a single stroke. This innovation significantly increases production capacity without the need to expand the production line.

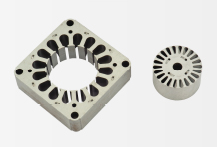

Automotive

The motor core is made of stacked materials with a thickness less than 0.5mm. Minimizing stamping burrs and ensuring equal cutting surfaces are critical to improving motor efficiency. INGYU high speed stamping with stable bottom dead center, which helps reduce burrs and prolongs the service life of dies.

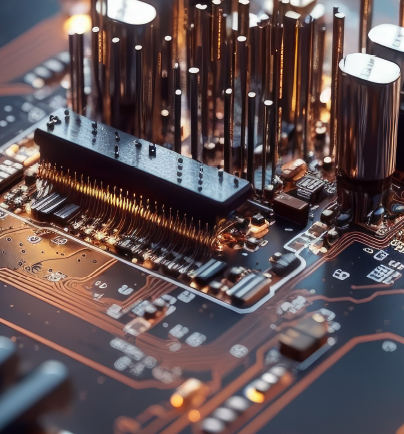

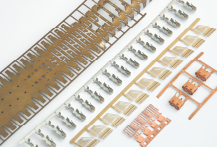

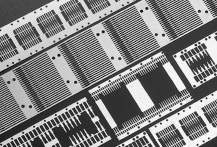

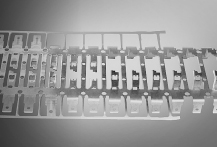

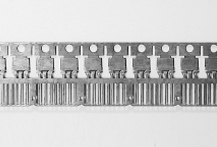

Electronic Components

The electrical connector manufacturing process transforms flat sheet metal into user-defined shapes using various metal forming techniques, including blanking, punching, bending, coining, and piercing. These connectors are essential in industries such as aerospace, automotive, and healthcare.

Optical Display

The thickness of aluminium components in tablets and laptops has been

reduced from 0.3mm to 0.2mm, cutting aluminium usage by 33%. This thinning

process supports environmental, social, and governance (ESG) goals by

reducing mining and promoting sustainable manufacturing practices in

electronics.